IZIQINISEKISO

Zonke iimodeli eziboniswe kule khathalogu zihambelana ne-ECE 22.05 okanye i-ECE 22.06 standard yamazwe ngamazwe, iDOT FMVSS NO.I-218, iSatifikethi esiSinyanzelo saseTshayina, njl.

Uphawu lokuqala olubalulekileyo lwe-Aegis kukuthembeka kwayo njengomvelisi;ukuthembeka okungekho kuphela umphumo wobuchwephesha bayo, kodwa kwakhona, kwaye ngaphezu kwayo yonke into, ukuzinikela kwayo okuqhubekayo kukhuseleko kunye nomgangatho.

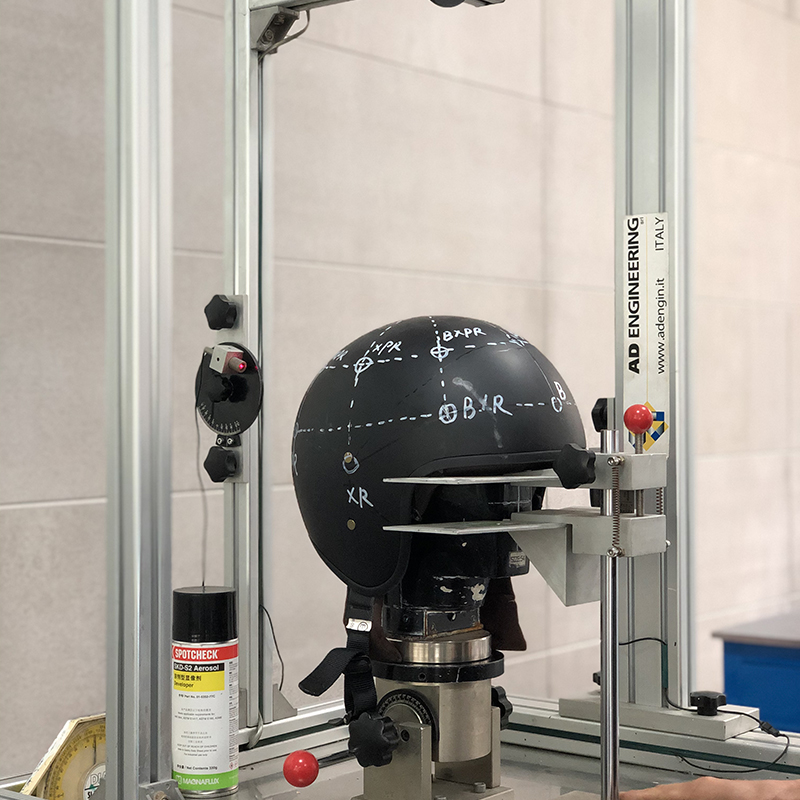

IILEBHARI ZANGAPHAKATHI

I-Aegis imisela elabhoratri yangaphakathi edlala indima ebalulekileyo kwinqanaba lophuhliso lwemveliso kunye nemveliso yemihla ngemihla. Ukuze ihlangabezane ne-ECE / DOT / CCC njl. njl. ngaphandle kwi-helmets, ngelixa ii-visors ziphantsi kovavanyo lwe-optical kunye nokumelana.Izixhobo ezikhethekileyo kunye noomatshini ngaphezu koko zivumela ukwenziwa kovavanyo olufunwa yeminye imimiselo yamazwe ngamazwe. Izigcina-ntloko kunye neevisor zigqithiselwa kwiilabhoratri zangaphandle ezizimeleyo eziqhutywa liqela lesithathu, ukuze kufumaneke i-homologation kunye nesiqinisekiso, ngoko ke ukuvumela ukuveliswa kobuninzi ukuba kuqalise. .Ilabhoratri iqhuba iimvavanyo ezongezelelweyo zokusebenza nazo, ezingafunwayo yimimiselo, kwiimveliso ezigqityiweyo kunye namacandelo ahlukeneyo, kwinqanaba lophuhliso kunye nemveliso yemihla ngemihla, eyenziwa ngokuthathwa kweesampuli.Lilonke, lo msebenzi ukhankanywe ngasentla uphumela kuvavanyo lweehelmethi ezimalunga nama-2,000 minyaka le.

CNC MACHINING

Emva kokuba iziko le-R & D lenze idatha ye-3D, iya kunikezelwa kwi-CNC ukwenza i-molds.Igama elithi CNC limele 'ulawulo lwamanani ekhompyutheni', kunye nenkcazo ye-CNC yomatshini kukuba yinkqubo yokuvelisa i-subtractive eyenza ngokuqhelekileyo isebenzise ulawulo lwekhompyutha. kunye nezixhobo zoomatshini zokususa iileyile zezinto eziphathekayo kwi-stock piece-eyaziwa ngokuba yinto engenanto okanye i-workpiece-kwaye ivelise inxalenye eyenziwe ngokwezifiso.Iindawo ezisecaleni eziveliswe yi-CNC automation azinaziphene ezicacileyo kwaye zilungile.

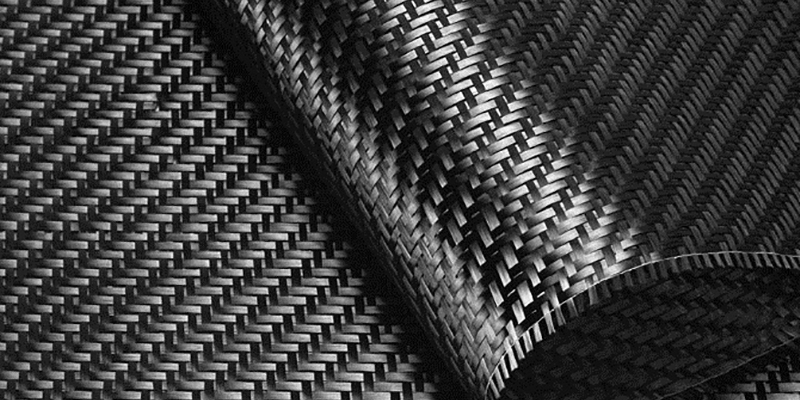

IZINTO

I-Aegis igxile kwiihelmethi ezidibeneyo.Ulwazi- njani kunye nophando kwimveliso yeCarbon/Kevlar/Fiberglass ngundoqo kwi-Aegis.

IMULTICOMPOSITE EVOLUTION

Ukusetyenziswa kwezinto ezilungileyo kakhulu kuthi akwanele.Uphando oluqhubekayo kunye novavanyo luzise i-Aegis indawo yokuvelisa amaqokobhe e-helmet anamandla kakhulu kodwa alula.

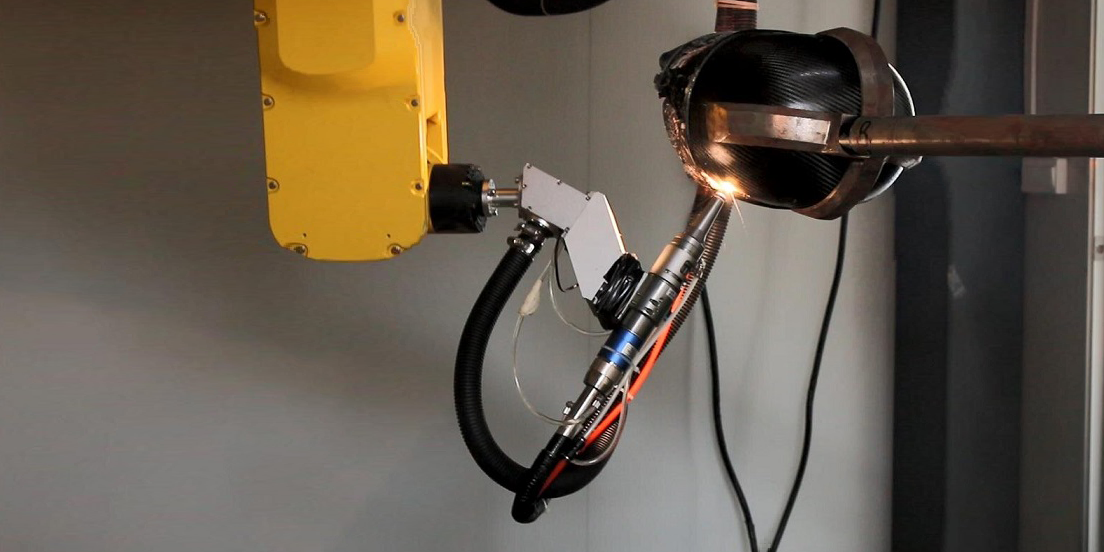

LASER UKUSIKA

Apha isigcina-ntloko sinikwa isimo saso sokugqibela.Zonke iiprotrusions ezidalwe kwimveliso zinqunyulwa.Ukuvuleka kwe-visor kunye ne-ventilation kutshiswa kwi-helmet shell nge-laser.Ekugqibeleni isigcina-ntloko siyajongwa ukuqinisekisa ukuba sinobukhulu obuchanekileyo bezinto eziphathekayo kunye nobunzima.

UKUPEYINTA

Nangona amanyathelo amaninzi emveliso enziwe ngokuzenzekelayo namhlanje, akunakwenzeka ukukhupha umsebenzi wezandla kwezinye iindawo.I-Aegis idibanisa umsebenzi wezandla kunye ne-automation kwimveliso ukuqinisekisa umgangatho ophezulu kakhulu kuzo zonke iinkcukacha.

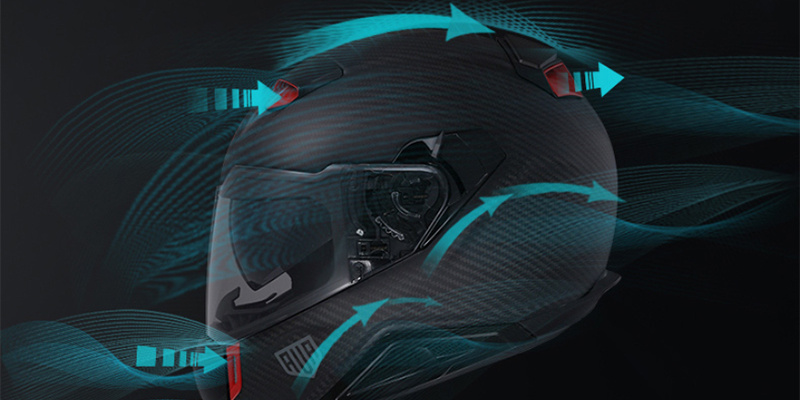

INKQUBO YOKUPHUMULA

Ukungenisa umoya kusebenza ngakumbi ukuba umoya unendlela yokuphuma.Iihelmethi ze-Aegis zixhotyiswe nge-ventilation yomoya kunye ne-extractors kunye nenkqubo yokuhambisa umoya ngaphakathi kokukhusela i-polystyrene iqinisekisa ukuba umsebenzisi ugcina ubushushu obuphezulu ngaphakathi kwesigcina-ntloko.Umoya ungena ngaphambili uqukuqela ungene kwiqokobhe le-EPS elingaphakathi kwaye uphume kwii-extractors ezingasemva, ngaloo ndlela ufumana intuthuzelo efanelekileyo nakuhambo olude.